Product Specification

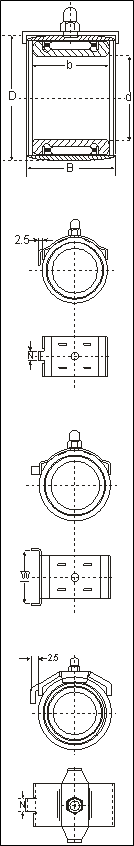

The Bearing arrangements of the bottom rollers in the drafting system in spinning frames and roving frames require uniform running in order to guarantee the highest quality yarn. Bottom Roller Bearings are precision needle roller bearings which excel through their high load carrying capacity and extremely accurate radial and side face run-out. A wide variety of Bottom Roller Bearings for supporting bottom rollers in Speed Frames and Ring Spinning Frames are available off the shelf while specific requirements are also catered to.

Bottom Roller Bearings are available with one piece plastic cage or split type steel cage, lubricating nipple and side or centre locating clip for various types and of Roller accommodate some misalignment in the Roller Stand and helps in distributing the load uniformly These are protected from contamination of dust and fly particles by particularly effective gap seals

Bottom Roller Bearings are available with one piece plastic cage or split type steel cage, lubricating nipple and side or centre locating clip for various types and of Roller accommodate some misalignment in the Roller Stand and helps in distributing the load uniformly These are protected from contamination of dust and fly particles by particularly effective gap seals

MOUNTING PROCEDURE

To mount the bearings on the stands, we recommend the following :

1 Light mineral oil should be applied on the journal seating. Care should be taken to ensure that the faces and journals of the bottom rollers are neither damaged or dirty .

2. The inner rings is a press fit on the journal A special tubular dummy should be placed against the Inner ring face and the force for mounting should be applied uniformly until the bearing ring abuts the face of the bottom roller. No sharp tool or pointed edge should be used against the bearing ring face. Use of a pneumatic cylinder is recommended over other methods.

3. After the rollers are placed on the stands and the holders are in position, the alignment in the longitudinal direction should be checked to ensure true running. Excessive misalignment can reduce the service life of the bearings

MAINTENANCE

Bottom Roller bearings can to a certain degree be called 'maintenance free". A few routine checks mentioned below will however assist in detecting any malfunction. 1. When the machinery is running, an industrial stethoscope may be used to monitor bearing noise. 2. Follow Lubrication routine of renewing (good quality) Lithium based grease every 4 to 6 months.

Note :

On delivery.  Bottom Roller Bearings are coated with a rust preventive (greasy when touched) but they are not greased Hence all bearings should be greased before use.

Bottom Roller Bearings are coated with a rust preventive (greasy when touched) but they are not greased Hence all bearings should be greased before use.

Select the Type of Bottom Roller Bearing Required

Legal Disclaimer : The data provided is for informational purpose only. Technical data is subject to change from time to time without prior information. The Company cannot be held liable for any inadvertent accuracy in data. Other Brand Names & Companies mentioned are for reference purpose only & without any intent to infringe.

Holder Type Locating Bearing

Technical Specification

|

MRS

|

Dimensions

|

Holder

|

Interchangeable

|

|

d mm

|

D mm

|

b mm

|

B mm

|

Type N

Centre

|

Type W

Side

|

INA

|

SKF

|

A PHP Error was encountered

Severity: Notice

Message: Undefined variable: count

Filename: views/product_bottom.php

Line Number: 122

A PHP Error was encountered

Severity: Notice

Message: Trying to access array offset on value of type null

Filename: views/product_bottom.php

Line Number: 122

A PHP Error was encountered

Severity: Notice

Message: Trying to access array offset on value of type null

Filename: views/product_bottom.php

Line Number: 122

|

No records found

|

A PHP Error was encountered

Severity: Notice

Message: Undefined variable: count

Filename: views/product_bottom.php

Line Number: 130

A PHP Error was encountered

Severity: Notice

Message: Trying to access array offset on value of type null

Filename: views/product_bottom.php

Line Number: 130

A PHP Error was encountered

Severity: Notice

Message: Trying to access array offset on value of type null

Filename: views/product_bottom.php

Line Number: 130

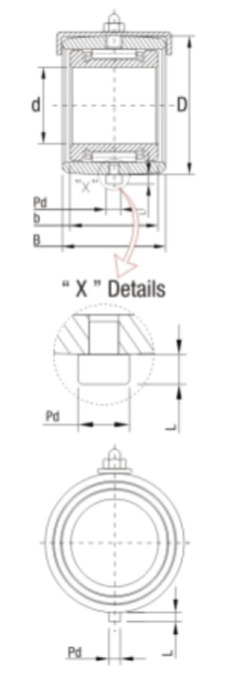

Pin Type Locating Bearing

Technical Specification

|

MRS

|

Dimensions

|

Holder

|

Interchangeable

|

|

d mm

|

D mm

|

b mm

|

B mm

|

Pd x L

|

INA

|

SKF

|

A PHP Error was encountered

Severity: Notice

Message: Undefined variable: count1

Filename: views/product_bottom.php

Line Number: 230

A PHP Error was encountered

Severity: Notice

Message: Trying to access array offset on value of type null

Filename: views/product_bottom.php

Line Number: 230

A PHP Error was encountered

Severity: Notice

Message: Trying to access array offset on value of type null

Filename: views/product_bottom.php

Line Number: 230

|

No records found

|

A PHP Error was encountered

Severity: Notice

Message: Undefined variable: count1

Filename: views/product_bottom.php

Line Number: 238

A PHP Error was encountered

Severity: Notice

Message: Trying to access array offset on value of type null

Filename: views/product_bottom.php

Line Number: 238

A PHP Error was encountered

Severity: Notice

Message: Trying to access array offset on value of type null

Filename: views/product_bottom.php

Line Number: 238

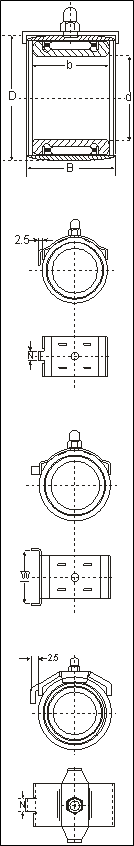

Special Bottom Roller Bearings

Technical Specification

|

MRS Bearing No

|

Interchangeable

|

|

M 75100

|

F-84174

|

|

M 76220

|

UW 2136.20

|

|

M 75222

|

UW 2136.22

|

|

M 75324

|

F-94733

|

| M 76100 |

F-56875-1 |

| M 75400 |

F-52364 |

| M 75599 |

F-35303 |

| M 75788 |

F-29934 |

| M 75888 |

F-22648 |

| M 76088 |

F-21460 |

| M 75688 |

F-32664 |

| M 77400 |

F-23482 |

| M 75900 |

UL 32-0036128 |

| M 76311 |

NFB 15Z-3 |

| M 76411 |

NFB 18-2 |

| M 76511 |

2B 19Z-3A |

| M 76611 |

NFB 19Z-1B |

| M 76711 |

NFB 16-2 |

| M 76811 |

2B 18-3 |

| M 76900 |

BR 3600 SPL (SPL CAGE) |

| M 77826 |

TEX Z 232 |

| M 77322 |

BR 3222 SPL (16 NEEDLES) |

| M 77500 |

BR 3200 SPL (16 NEEDLES) |

| M 77600 |

BR 2800 SPL |

| M 77799 |

BR 4319 SPL |

| M 77900 |

BR 3216.3 SPL |

| M 77024 |

BR 322424 SPL (18 ROLLERS) |

| M 77299 |

BR 5525 / NSC SPEED FRAME |

| M 78022 |

EJECT 200120 |

| M 78270 |

BR 3220 SPL (16 ROLLERS WItd L CLIP) |

| M 78320 |

BR 3220 (16 ROLLERS) |

| M 78424 |

BR 3224 (16 ROLLERS) |

Bottom Roller Bearings are available with one piece plastic cage or split type steel cage, lubricating nipple and side or centre locating clip for various types and of Roller accommodate some misalignment in the Roller Stand and helps in distributing the load uniformly These are protected from contamination of dust and fly particles by particularly effective gap seals

Bottom Roller Bearings are available with one piece plastic cage or split type steel cage, lubricating nipple and side or centre locating clip for various types and of Roller accommodate some misalignment in the Roller Stand and helps in distributing the load uniformly These are protected from contamination of dust and fly particles by particularly effective gap seals

Bottom Roller bearings can to a certain degree be called 'maintenance free". A few routine checks mentioned below will however assist in detecting any malfunction. 1. When the machinery is running, an industrial stethoscope may be used to monitor bearing noise. 2. Follow Lubrication routine of renewing (good quality) Lithium based grease every 4 to 6 months.

Bottom Roller bearings can to a certain degree be called 'maintenance free". A few routine checks mentioned below will however assist in detecting any malfunction. 1. When the machinery is running, an industrial stethoscope may be used to monitor bearing noise. 2. Follow Lubrication routine of renewing (good quality) Lithium based grease every 4 to 6 months.

Bottom Roller Bearings are coated with a rust preventive (greasy when touched) but they are not greased Hence all bearings should be greased before use.

Bottom Roller Bearings are coated with a rust preventive (greasy when touched) but they are not greased Hence all bearings should be greased before use.